Steam Sterilizer (Autoclave)

APSR-01

The Autoclave Steam Sterilizer has a touch panel with Human Machine Interface (HMI), signal conditioning units, safety circuits and emergency switch. The Autoclave Steam Sterilizer is controlled at all time by the HMI. Which contains the operation automatic screen, manual, trend graph, parameter, dynamic and password, etc.

In order to destroy the uniqueness of microbes and bacteria, the Autoclave Steam Sterilizer is designed to withstand high-pressure steam and temperature, and use pure steam as the heating medium.

When the sterilization temperature is 121℃, the acceptable range of no-load and full-load's temperature and heat distribution is within plus or minus 0.5℃.

Features

- The panel use LCD touch screen control.

- Program Flow: PLC control. Easy operation. Providing three sterilization programs or customize specifications as customers' requirements.

- Simple & Safe operation: The automatic program provides complete and safe control to ensure safe operating condition.

- Temperature recorder for continuous monitoring and recording the sterilization process.

- Vacuum filter: online SIP sterilization, completed test report, heating and drying for the filter shell to prevent the filter from clogging and moist bacteria.

- The pure steam inlet can be used for condensation sampling, online inspection, dryness or steam quality test.

- The inner carcass and interlayer pressure can reach 3.5 bar.

- The heat distribution of inner carcass can reach temperature within ± 0.5°C.

- Check the temperature of the holes, all the holes can drain water completely.

- The inner carcass is a special design so that all water can be completely drained.

- Inner carcass vacuum leak test, heat penetration test, steam quality test.

- Can be connected to an external computer to calculate the Fo value automatically.

- Can implement complete FAT, SAT, DQ, IQ, OQ, PQ with the owner together.

- During the warranty period, technicians will come to your factory for free service.

- Human-machine has 4-level control authority management and records.

- Comply with EN285、HTM2010、PDA TR1、UPS, etc.

Applications

- Pharmaceutical / Hospital / Laboratory / Food / Biotech Industries.

- For rubber stopper, glass bottle, metal bottle, aluminum cap, tank, waste.

- For machine, filling & stainless steel fittings, clothes, sterilization clothes, filter, and filter element.

- For terminal sterilization, PVC, PP Plastic bottle, vials, ampoule, non-infusion, and soft bag.

- For ampoule sterilization and leaking test.

- For animal feed and animal caglensese.

- For equipment and system components.

- For tool, instrument.

- For contact lenses.

- For wrapped or unwrapped material sterilization.

- For material sterilization, such as membrance container, PVC or PP, etc.

Specification

- Sterilization chamber in SUS 316, SUS 316l and SUS 316Ti stainless steel.

- Piping and valves directly connected with chamber in stainless steel.

- Chamber piping all valves and fittings are sanitary class.

- Insulation by Glass wool.

- Automatic temperature controller.

- Automatic temp. Recorder - 6 points or 12 points.

- Sealed Door Packing: Use heat-resistant silicon rubber material ring packing.

- Absolute air vent filter for prevention of sterilized product contamination.

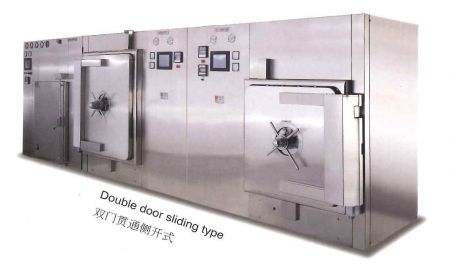

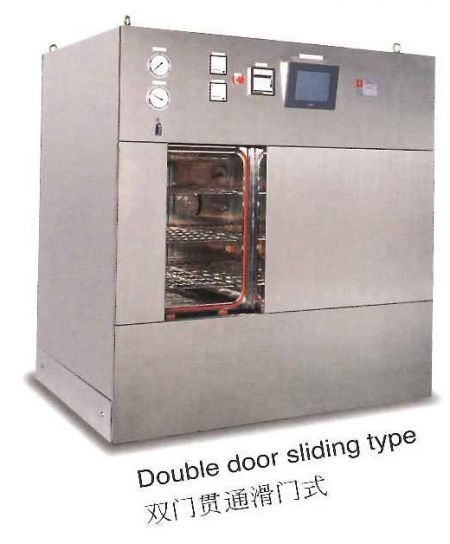

- One door or pass through type double doors.

- Single wall (cylindrical chamber) or double walls (parallelepiped chamber) body.

- All control and safety components are adapted to the higher temperature and pressure.

- Option: RS 232 Interface is for connecting to an external computer.

| Standard Model (APSR, ASWR, APST, EOG) | Capacity (Liter) | Steam Consumption (kg/Hr) | Chamber Dimension (W x H x D) (m/m) | External Dimension (W x H x D) (m/m) | ||||

|---|---|---|---|---|---|---|---|---|

| W | H | D | W | H | D | |||

| 200 | 200 | 55 | 500 | 500 | 800 | 1200 | 2000 | 1100 |

| 360 | 360 | 60 | 600 | 600 | 1000 | 1350 | 2100 | 1300 |

| 480 | 480 | 100 | 600 | 800 | 1000 | 2000 | 2150 | 1300 |

| 600 | 600 | 120 | 600 | 1000 | 1000 | 2000 | 2150 | 1300 |

| 1000 | 1000 | 150 | 800 | 1000 | 1250 | 2800 | 2300 | 1550 |

| 1200 | 1200 | 150 | 1000 | 1000 | 1200 | 3100 | 2300 | 1500 |

| 1500 | 1500 | 160 | 1000 | 1000 | 1500 | 3100 | 2300 | 1500 |

| 1800 | 1800 | 160 | 1000 | 1200 | 1500 | 3100 | 2500 | 1800 |

| 2160 | 2160 | 200 | 1200 | 1200 | 1500 | 3300 | 2500 | 1800 |

| 5400 | 5400 | 250 | 1200 | 1500 | 3000 | 3300 | 2800 | 3300 |

※ We can accept customer specify specification.

Equipment Arrangement

The Autoclave has a central control panel, which houses the programmable logic controller (PLC), signal conditioning units, safety circuits and emergency switch. The Autoclave is controlled at all time by the PLC. Which contains the operation automatic screen, manual, trend graph, parameter, dynamic and password etc, screen.

Construction & Structure

- Sterilization chamber in SUS 316, SUS 316L and SUS 316Ti stainless steel.

- Piping and valves directly connected with chamber is stainless steel.

- Chamber piping all valves and fitting are sanitary class.

- Insulation by Glass wool.

- Automatic temperature controller.

- Automatic temp. Recorder-6 points or 12 points.

- Sealed door packing: Use heat-resistant silicon rubber material ring packing.

- Absolute air vent filter for prevention of sterilized product contamination.

- One door or pass through type double doors.

- Single wall (cylindrical chamber) or double walls (parallelepiped chamber) body.

- All control and safety components are adapted to the higher temperature and pressure.

- Option: RS 232 Interface for connection to an external computer.

- Our plant assure sterilization in conformity with good manufacturing practices for LVPs, SVP, etc. and in accordance with cGMP issued by FDA. In short, excellent engineering coupled with efficient manufacturing.

Performance

Special thanks to the following Pharmaceutical and Biotechnology factories for purchasing our equipment to build biotech pharmaceutical factory that meets PIC/S GMP international standards.

- Pegavision Corporation

- Virbac (Taiwan) Co., Ltd.

- Adimmune Corporation

- Savior Lifetec Corporation

- PT. Interbat Pharma

- Y F Chemical Corporation

- Bioteque Corporation

- PT. Interbat Pharma

- China Chemical & Pharmaceutical Co., Ltd. (Factory at Xinfeng)

- United Biomedical, Inc., Asia

- Sinphar Pharmaceutical Co., Ltd.

- Innova Pharma.

- Yung Sheng Optical Co., Ltd.

- Equitran Technologic

- PT. DARYA Laboratory

- Chi Sheng Pharma & Biotech Co., Ltd.

- PT. PHAROS

- Genovior Biotech Corporation

- PT. LAIP Laboratory

- Genovate Biotechnology Co., Ltd.

- Astar Chemical & Phar Co., Ltd.

- Oasis Chemical Industries Co., Ltd.

- Amaran Biotechnology, Inc.

- PT. MEIJI Pharma

- PT. MEPRO Pharma

- DANAPHA PHARMACEUTICAL

- San Heh Pharmaceutical Corporation

- Camax Optical Corporation

- Wu Fu Laboratories Co., Ltd.

- Panbiotic Laboratories Co.,Ltd.

- China Chemical & Pharmaceutical Co., Ltd. (First Factory at Tainan)

- PT. SANBE

- Synpac-Kingdom Pharmaceutical Co.,Ltd.

- Tai Yu Chemical & Pharmaceutical Co., Ltd.

- Tah-An Chemical & Pharmaceutical Co., Ltd.

- Astar Chemical & Phar Co., Ltd.

- Shinlin Sinseng Pharmaceutical Co., Ltd.

- SciVision Biotech Inc.

- PT. PHAPROS

- PT. ERELA

- PT. MEPRO Pharma

- PT. LUCAS Pharma

- PT. SANBE Pharma

- Shm Everbiz Inc.

- Standard Chem & Pharm Co., Ltd.

- China Chemical & Pharmaceutical Co., Ltd. (Third Factory at Tainan)

- Gallery

- Related Products

Superheated Water Sterilizer (Autoclave)

APWR-01

Autoclave Superheated Water Sterilizer is a highly efficient sterilization process for airtight...

DetailsSteam-Air Mixture Sterilizer (Autoclave)

APST

Sterilization on Autoclave Steam-Air Mixture Methods is designed to sterilize liquids in closed...

DetailsE.O.GAS Sterilizer

E.O.GAS Sterilization can be used to sterilize objects that are not suitable for high temperature...

Details

Steam Sterilizer (Autoclave) - Autoclave Steam Sterilizer | Taiwan-Based Pharmaceutical & Biotech Manufacturing Equipment Manufacturer | E CHUNG MACHINERY CO.

Located in Taiwan since 1975, ECMC (E CHUNG MACHINERY CO.) has been a pharmaceutical and biotech processing equipment manufacturer. Main products, including Steam Sterilizer (Autoclave), autoclaves, WFI, water systems, pure steam generators, superheat water sterilizers, vial washing machines, tunnel sterilizers, and, in particular, hot air and steam sterilizers.

ECMC (E CHUNG) company is a professionl experienced manufacturer in the pharmaceutical sterilization industry more than 48 years so that our customers located worldwide. Sterilization machines are manufactured in line with current international standards (EU standards, US standards, GMP and GAMP, etc.).

ECMC (E CHUNG) has been providing customers high-quality cGMP pharmaceutical and biotech processing equipment, both with advanced technology and 48 years of experience, ECMC (E CHUNG) ensures each customer's demands are met.