Sanitary Mixing Tank

Raw material feeding to High Speed Mixer can be manual through the fully open lid, or completely automatic through suitable inlets on the lid. Conical mixing bowl structure helps preventing an adhesion of raw material and providing a smoother flow of materials inside the bowl. Finished product is discharged by centrifugal force tghrough pneumatic discharge valve into product container or directly to Fluid Bed Dryer bowl.

High efficiency, short mixing time, the dry powder mixing to be finished is about 1 to 3 minutes, the wet grains making to be completed is about 3 to 5 minutes. No contamination, main agitator and chopper shaft with AIR SEAL to avoid powder pollution. Safety device in order to prevent operators from danger. Control system independently, easy to operate. Mixing tank designed to waterproof, products change or off duty that easy to wash clean inside.

High mobile with movable wheel and fixed support socket, easy to move. Safety, sanitation, high mixing efficiency, apply to high quality products, both economy and durable.

Features

- Meets the cGMP requirement. Multi-function including mix, spray drying, granulating, film coating in one equipment.

- Heavy duty structure. Interior wall had been special polishing treatment to get very fine surface and easy clean internal surface.

- Using high efficient air filter to ensure good intake air quality. Good collection effect. The filter pocket selects the anti-static electricity material quality, could adjust shakes times and frequency individually.

- Friendly design with good control function comes with PLC interface and touch panel. It's easy use and also safe during the operation. Various option devices are available to adapt into the equipment depends on the application or the users' demands, such as: Temp. recorder, CIP self-cleaning, vacuum suction dump system, and so on.

Applications

- Suitable for pharmaceuticals, foods, chemicals, cosmetics, electronics, ceramics, rubbers and plastics industries, etc. Raw material binder of mixing and granulating.

Specification

- Mixiing tank. (CIP/SIP).

- Sterile injection.

- Oral liquid.

- Eye drops.

- Big infusion.

- Homogeneous mixing tank.

Specification

| Model | Total Contents | Working Batch | Agitator Drive | Agitator Speed | Chopper Drive | Chopper Speed | Dimension W x L x H | Weight |

|---|---|---|---|---|---|---|---|---|

| UNIT | LITER | KG | KW | RPM(60HZ) | KW | RPM(60HZ) | MM | KG |

| ECSM-20 | 20 | 5 | 1.5 / 2.2 | 215 / 140 | 1.1 / 1.5 | 1720 / 3440 | 540 x 1543 x 1238 | 200 |

| ECSM-100 | 100 | 30 | 3.7 / 5.5 | 172 / 120 | 1.5 / 2.2 | 1720 / 3440 | 850 x 2040 x 1700 | 850 |

| ECSM-150 | 150 | 60 | 5.5 / 7.5 | 172 / 120 | 2.2 / 3.7 | 1720 / 3440 | 990 x 2250 x 2000 | 100 |

| ECSM-250 | 250 | 100 | 10 / 12 | 172 / 120 | 3.7 / 5.5 | 1720 / 3440 | 1190 x 2370 x 2150 | 1500 |

| ECSM-400 | 400 | 150 | 22.5 / 26.5 | 145 / 95 | 3.7 / 5.5 | 1720 / 3440 | 1720 x 2650 x 2800 | 2500 |

| ECSM-600 | 600 | 200 | 37 | 120 | 10 | 1720 / 3440 | 1720 x 3000 x 2800 | 3200 |

※Welcome customised requirements。

CGMP-Design Function: Complying With CGMP Requirements

Mixing different powders evenly at a horizontal level with high speed, adding appropriate adhesive and granulating with the knife inside of the barrel, then taking out the finished product from the discharge port. Usually, it takes about 1 to 3 minutes for mixing dry powders, and takes about 3~5 minutes to complete the granulation process.

Mechanical Mechanism

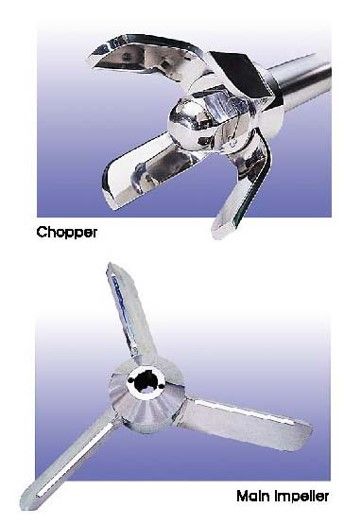

Complying GMP requirements for High Speed Mixer/Granulator Design, the structure is safe and pollution-free. Simple operation. Easy to clean. The material is AISI316L# stainless steel. The equipment is composed of mixing barrel, mixing blade, granulating blade, base, motor transmission device, discharging device and control system. And the control box adopts waterproof and dustproof device.

Agitation Vessel

- Waterproof design, the interior can be cleaned by water.

- It's a cone-round mixing tank, which can makes the surrounding powder and adhesive flow to the center to increase the mixing effect.

- The lid of the barrel is equipped with raw material insertion holes and air dust collecting filter bags to prevent pollution that causing from dust circulating.

- The opening and closing action of the upper cover adopts air-pressure pneumatic device, and attached a safety protection switch.

- Large type can be installed CIP cleaning device.

Anti-Pollution Device: Airtight

- Pharmacy / Biotechnology ⇒ Western medicine: powder granulation, true round granulation, film coating, sustained-release medicine and other granulation and drying. Chinese medicine: granulation and drying of concentrated granules.

- Food ⇒ Seasoning: High fresh powder, monosodium glutamate, etc. Brewing bag: Three-in-one brewing bag, instant food and drink, etc.

- Chemical industry ⇒ granulation and drying of raw materials, dyes and synthetic materials.

By the compressed air that passing through the 0.2μm absolute filter, entering the specially-designed air shaft seal of the mixing blade and granulation cutter to prevent pollution caused by entering the rotating shaft.

Discharge device

- Fast action. The finished products can be discharged in a very short time.

- Adopting air-pressure pneumatic device, and the cover is attached with a safety protection switch.

The control system is easy to operate.

- Both the mixing motor and the granulating cutter motor have two-stage speed adjustment, high-speed and low-speed.

- Safe and complete protective measures device.

- The mixing and granulation time is automatically controlled, and the elapsed time can be detected.

- Each has its own operation switch and loading detection instrument.

- Gallery

-

-

Sanitary Mixing Tank

-

Sanitary Mixing Tank

-

Sanitary Mixing Tank

-

Sanitary Mixing Tank

-

Mixing Tank

-

Magnetic Mixing Tank with Scale

-

Magnetic Mixing Tank with Scale

-

Magnetic Mixing Tank with Scale

-

Magnetic Mixing Tank with Scale

-

Magnetic Mixing Tank with Scale

-

Mixing Tank (150L)

-

Super Mixer (High Speed Mixer and Wet Granulator)

-

Super Mixer (High Speed Mixer and Wet Granulator)

-

Super Mixer (High Speed Mixer and Wet Granulator)

-

Mixing Tank (50L~18000L)

-

Homogeneous Tank

-

Sanitary Mixing Tank - Sanitary Mixing Tank | Taiwan-Based Pharmaceutical & Biotech Manufacturing Equipment Manufacturer | E CHUNG MACHINERY CO.

Located in Taiwan since 1975, ECMC (E CHUNG MACHINERY CO.) has been a pharmaceutical and biotech processing equipment manufacturer. Main products, including Sanitary Mixing Tank, autoclaves, WFI, water systems, pure steam generators, superheat water sterilizers, vial washing machines, tunnel sterilizers, and, in particular, hot air and steam sterilizers.

ECMC (E CHUNG) company is a professionl experienced manufacturer in the pharmaceutical sterilization industry more than 48 years so that our customers located worldwide. Sterilization machines are manufactured in line with current international standards (EU standards, US standards, GMP and GAMP, etc.).

ECMC (E CHUNG) has been providing customers high-quality cGMP pharmaceutical and biotech processing equipment, both with advanced technology and 48 years of experience, ECMC (E CHUNG) ensures each customer's demands are met.